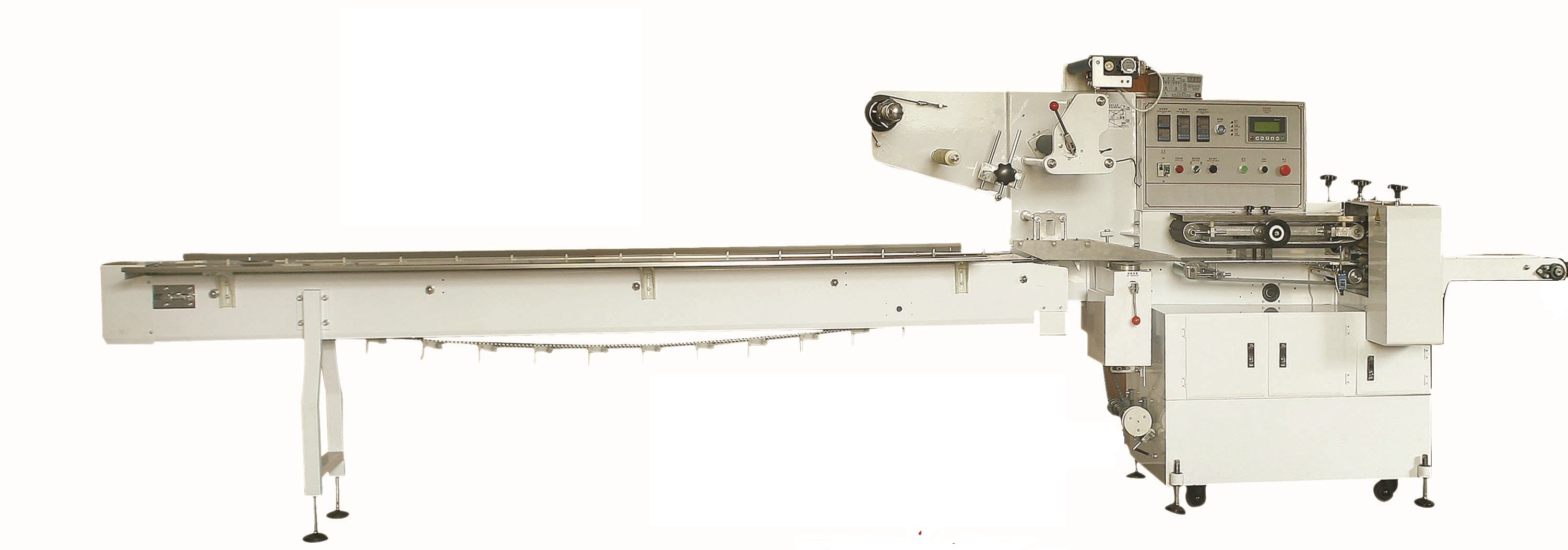

1. Compact design and easy operation. 2. Automatic on-site stop. 3. Digitally indicating the size of the film speed of wrapping turnout and temperature. 4. English-chinese touch screen. 5. Speed control via A.C. invertors. Film control via servo motor. ( we also can manufacture auto flow packing machinery with two servo motors three servo motors etc.) 6. Photoelectric cell and dual tracking without mechanical contact.

A wide range wrapping applications such as: different bottles ( yoghourt bottles juice bottles beverage bottles pesticide bottles etc.) food products ( vegetable with trays fruit with trays cup instant noodles cup milk tea etc.) cosmetic products ( nail polish bottles cosmetic cream bottles body cream bottle hair bottles etc. ) daily things ( tableware garbage rolls preservative film rolls gloves bandages plastic taps etc. ) healthcare products hardware etc.

Parameters

| Concept | Data |

| Model | HM-450/99 |

|

Roll Max. Width in mm |

450 |

|

Product Measurement ( mm) |

L: 90-400 W: 10-150 H: 5-40 |

| Capacity bags/min | 50-150 |

|

Machine Dimensions |

5000*965*1750mm |

| Types of Packaging Composite Film | Composite film such as OPP+PE, OPP+CPP, PET+PE, PET+CPP etc. |

| Machine Weight | 1000 kg |

| Power Required | 220V/AC, 1 phase, 50 Hz 3.66 KW |