High-speed Multifunctional AL-Plastic Blister Packing Machine 1. variable frequency stepless speed regulation, servo traction, adjust the stroke of a key in place. 2. The stroke can be adjusted within 40-120mm, which is easy to adjust with correct synchronization. 3. Adopts plate-type mould, positive-pressure forming, featured by batch number printing,creasing and cutting,aluminum-foil/plastics automatic feeding, automatic alarm for broken—piece and finished-piece and automatic stop etc. 4. Equipped with one set general feeder,which filling percentage reaches 99.5 and above. The feeder is fitted with dust exhaust joint so can overcome the dust problem duting feeding. 5. Adopts registering matching heating so that can reduce the heat energy loss of heater to the least, and the required temperature will be greatly reduced. 6. This machine has small volume, light weight, cramped structure, easy operation amd maintenance.

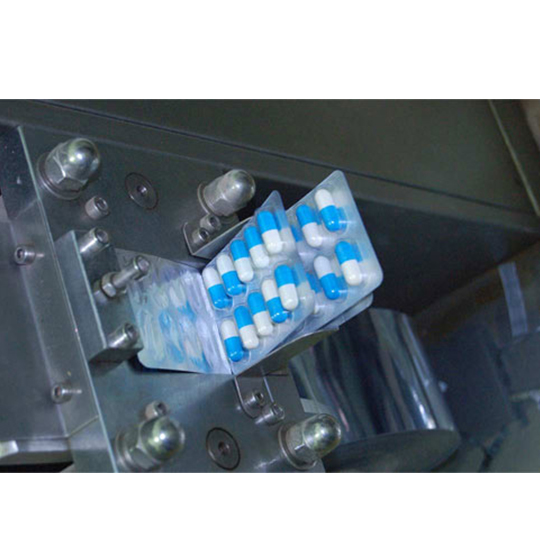

HM-180AP high-speed al-Plastic blister packing machine is the innovative packaging machine design. It is used for the pharmaceutical industry such as tablets, dragees, capsules; and also for foods and small metal parts, electronic components. It contains coil unwinding, aluminum feeding, blister forming, filling materials, waste recycling, plastic heat sealing, printing batch number, textured indentation, forum cutter display counting ten functions in one machine. The machine is pharmaceutical packaging technology improvement and implementation of GMP production equipment in China.

Within period of warranty

- Except for the consumable parts and the damaged parts are caused by artificial factor, we can replace the new component in free of charge only when the machine is operated and used under normal condition, while shipping cost should be paid by buyer.

- If on-site training and service is needed, the buyer should help the engineer of our company obtain the vias and prepay all the expense related to the service, including but not limited to traffic expense in China, the commission charge related to visa, air ticket, oversea traffic fee, accommodation rend, food expense etc. The training and technical service can be provided for free.

Beyond period of warranty

- We offer repair service if the machine is out of warranty period. Changing new components need to charge the cost of the component and shipping cost will be paid by buyer.

- For normal operation skills and other basic problems, we can provide you the related technical support through email or online answering.

- If whole life of the machine, you can send back the machine or spare parts at any time to our factory, our engineer will refresh and maintenance the parts on your machine as free, but cost is charge of buyers.

parameters

| Concept | Data |

| MODEL | HM-180AP |

| Cutting frequency | Al-plastic:25-50Times/min |

| Travel range | 30-120mm (freely adjusted) |

| Max. Forming Area | 160×110mm |

| Max forming depth | 25mm produced according to customer requirements |

| Total power | 3.8kw |

| Air volume flow | ≥0.2m3/min |

| Air pressure | 0.4-0.6Mpa |

| PVC specifications | 0.25-0.5×180mm |

| PTP specifications | 0.02-0.035×180mm |

| Dialysis paper | 50-100g×180mm |

| Overall dimensions | 3050×590×1550 mm |

| Weight | 780kg |